Graduate Co-op

Master’s and PhD students may complete 4 to 12 months of co-op experience in various types of organizations, including corporations, non-profit organizations, government agencies, startups and research institutions.

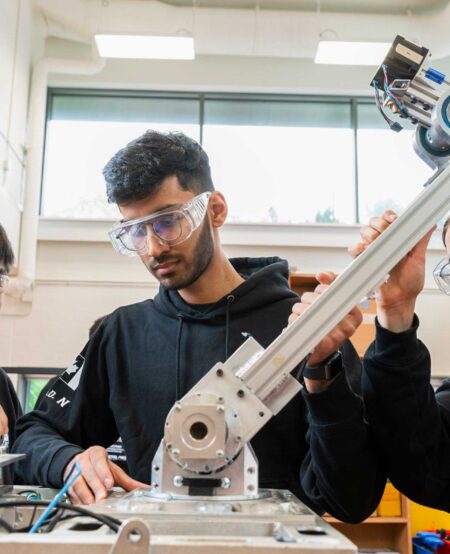

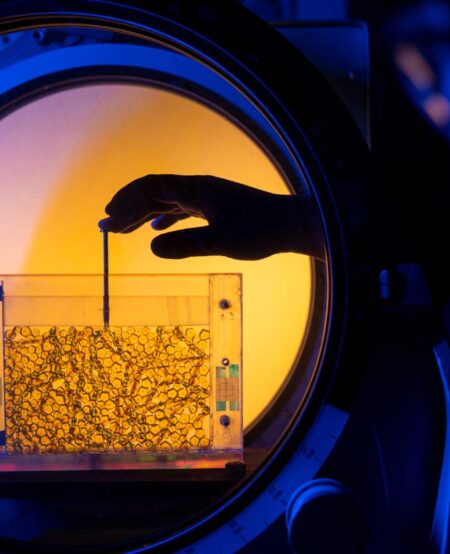

Get opportunities to connect with Canadian industry, learn about and analyze industry practices, and explore the latest methods of producing goods for industry and consumers. During your manufacturing engineering education, you will find a rewarding experience while you complete your Master’s degree and discover an exciting career pathway ahead of you.

Build a successful career in the manufacturing industry anywhere in the world. If you love to design and operate resource-efficient manufacturing plants this is the program for you.

Recommended 16 months full-time (minimum 12 months and maximum 24 months) or 40 months part-time (domestic only).

From the bleeding-edge tech we have at our disposal to the supportive professors, mentors and a multicultural student base, this program has it all. What’s more, you can customize your learning to create the best springboard to launch your career.

Co-op is an optional component of the Master of Engineering, Manufacturing Engineering program. McMaster established its graduate student co-op program in 2017, seeing it grow rapidly. Employers are quickly embracing it as a mechanism for recruiting talent and expertise.

There are several steps you must complete before you begin applying to co-op positions. Firstly, ensure you enrol in the Graduate Co-op Prep Course ENG 701 in September. You will also need approval from your program chairperson before accepting a co-op placement. Speak with the Centre for Career Growth and Experience (the Centre) if you have any questions.

If you intend to find a co-op placement remember that it is competitive, much like any job search. Start early and put in consistent effort throughout the school year to make connections and grow your network.

Here are some tips for finding your co-op position:

Employers

If you’re an employer interested in hiring graduate students for a co-op term connect with our the Centre for Career Growth and Experience (the Centre) to discuss listing your open opportunities.

Master’s and PhD students may complete 4 to 12 months of co-op experience in various types of organizations, including corporations, non-profit organizations, government agencies, startups and research institutions.

The EGS actively supports engineering graduate students through events, workshops, bursaries, and collaboration with various campus organizations, focusing on representation, community building, and academic and professional development.

Hamilton, also known as The Hammer or Steeltown, is a thriving city close to the U.S. border and Toronto, with easy access for students commuting from the Greater Toronto Area via the on-campus GO Bus Terminal.

Understand every step, from applying, to accepting your offer and joining us on campus!

Thank you for your interest in our Graduate Studies. Please fill out the form below, and we will connect with you to answer all of your questions.