Manufacturing is a priority among local economic development officials in cities world wide. It’s a sector of choice measured by employment, trade and wealth creation. And it can generate high value spin-off benefits, including local research and innovation.

That’s why the W Booth School at McMaster University is excited to participate in a manufacturing-related project meant to assist communities in developing countries.

The Wheelchair Development Project is a humanitarian initiative of the Rotary Club of Burlington, Ontario. The club is collaborating with a variety of partners — including a fellow club in the city of San Salvador — to help persons with disabilities access affordable wheelchairs. The goal is to design a basic, functional wheelchair that can be produced locally in low-tech fabrication shops using locally-sourced materials, components and labour.

This voluntary project is being led by Burlington Rotarian, Peter French. He’s a retired engineer with a wealth of manufacturing experience, and a strong commitment to mentorship and international service.

Peter heard about our school’s involvement in health-related design projects and contacted us in 2016. Several exploratory meetings led to a partnership that continues to evolve. A highlight to-date is the work of Franklin De La Cruz Dyer, a native of Venezuela who graduated from the W Booth School in 2017 (Master of Engineering Design, McMaster University).

Under the supervision of Dr. Robert Fleisig, and in close cooperation with Peter French, Franklin produced CAD drawings that incorporate the latest refinements to the design of the production wheelchair. The detailed 3D renderings — which represented a large part of Franklin’s graduation requirements — define the design and assembly information.

Franklin calls Rotary “an amazing organization” that opened his mind to a model of localized assistance that puts people and community first.

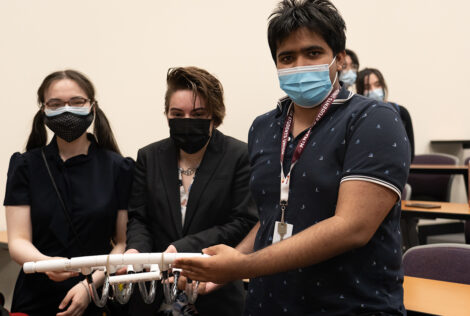

The next phase of the project is to design and make the basic metal cutting and tooling equipment required to produce the wheelchair in small batches. This equipment, along with an assembly manual based on Franklin’s work, would be packaged as a “wheelchair factory in a box” and shipped internationally to entrepreneurs in developing countries who to wish to serve local markets while growing a viable business.

“This is a hands-on innovation challenge that requires engineering students to carefully consider every step in a design and production process,” said Salman Bawa, Community Engagement Coordinator with the W Booth School. “It’s an example of the applied learning that differentiates our school.”