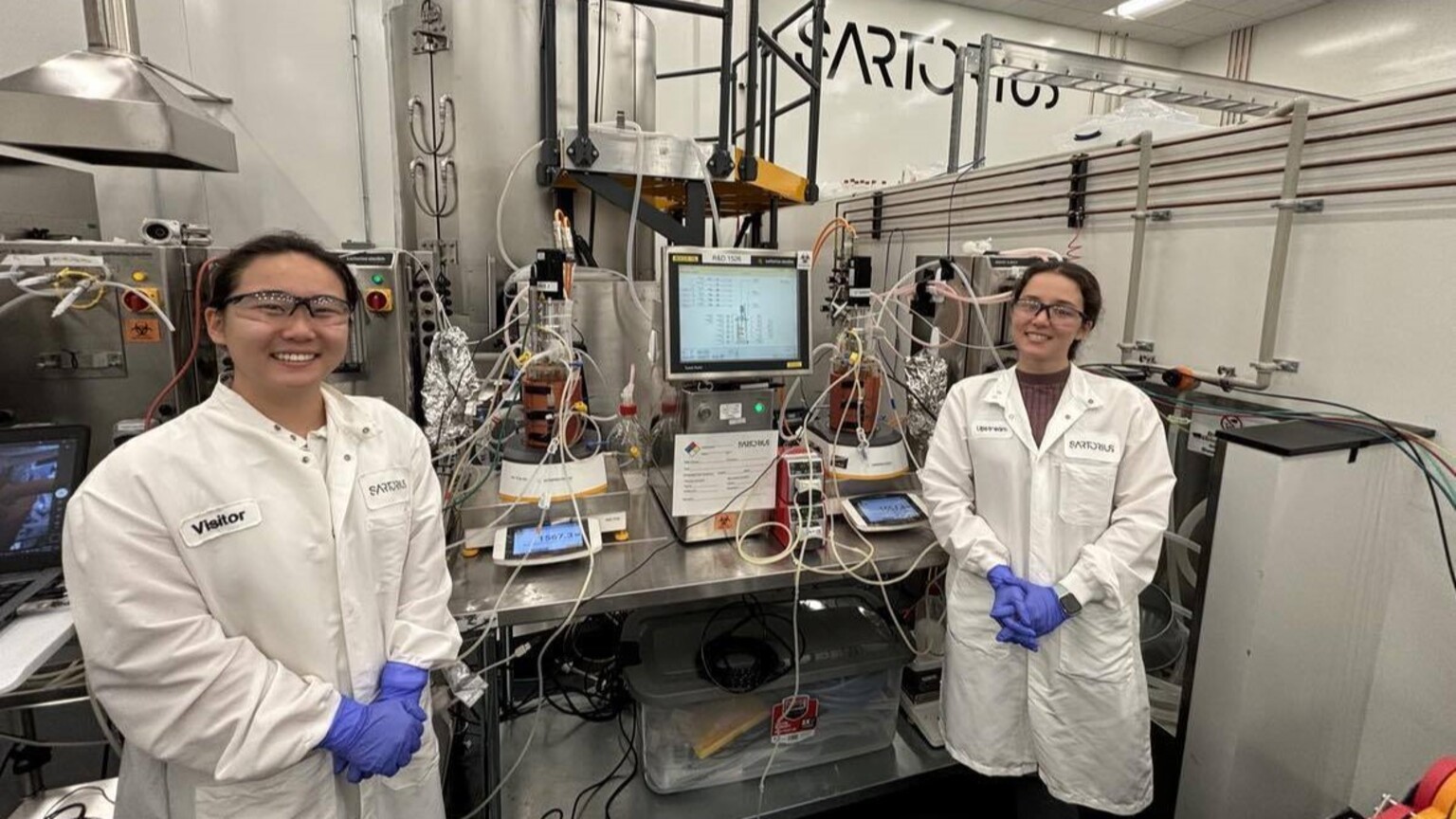

Chemical and Bioengineering undergraduate student Cindy Shu and Chemical Engineering PhD student Claire Velikonja travelled to Bohemia, New York to work alongside biotechnology company Sartorius’ Bioreactor Technologies Team.

Shu, the recipient of the Dean Chambers Experiential Learning and Discovery Fund and BioCanRX Summer Student Internship, and Velikonja, the recipient of the BioCanRX Lab Exchange Award, completed a two-week experiential research visit at the facility.

The frontier of biomanufacturing technology

At the Sartorius site, Shu and Velikonja learned about the bioreactor process used to produce monoclonal antibodies. These therapeutics are used in a variety of treatments, ranging from cancer to genetic diseases such as hemophilia and Parkinson’s disease. Being able to produce them in a cost-effective way is extremely important, especially in Canada where therapeutic cost plays a large factor in treatment accessibility.

McMaster University is poised to lead the Canadian investigation of the economical manufacturing of monoclonal antibodies through a planned expansion of the BioInterfaces Institute. This expansion will include the addition of bioreactors and will incorporate both automation and digital innovation with the goal of improving production efficiency. Shu and Velikonja credit their recent international experience at Sartorius for equipping them with the specialized knowledge and skills to contribute to this exciting initiative.

“Thanks to the time spent with such an extremely knowledgeable team at Sartorius, we now have first-hand knowledge in how to setup and run these bioreactors,” says Velikonja.

Associate Professor of chemical engineering and BioInterfaces Institute Co-Director, David Latulippe, believes that the unique experiential learning opportunity enjoyed by Shu and Velikonja has helped them understand the “big picture” of the frontier of biomanufacturing technology and has given them an appreciation for the roles that they can play at McMaster that will advance the field.

“The Canada Biomedical Research Fund and the Biosciences Research Infrastructure Fund McMaster received was instrumental in supporting the collaboration with Sartorius and made this incredible experience possible for Cindy and Claire. I’m thrilled to see them thinking now both within and beyond McMaster to consider how they might become leaders in our blossoming BioInterfaces Institute and in this exciting field of research.”

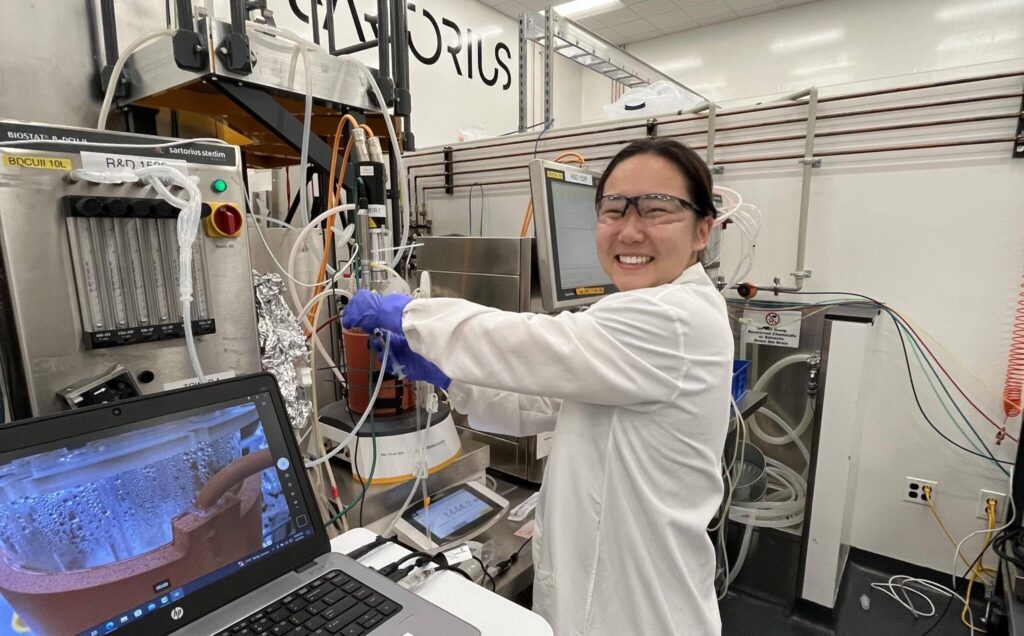

Shu and Velikonja have wasted no time in getting their hands dirty. In the first week back at the BioInterfaces Institute this September, they began implementing the learnings gleaned during their experience.

They adapted their current experimental planning procedures to include daily sampling of the cells for ongoing and future experiments, aiming to better characterize and understand the cell behavior. Additionally, they have applied lean methodologies to optimize the lab’s protocols and daily upkeep, ensuring greater efficiency and precision in their work.

The most valuable takeaway from this experience has been their opportunity to develop a comprehensive set of standard operating procedures (SOPs) for the first perfusion bioreactor experiment scheduled for the new year. By sharing their insights with the rest of the team, they have not only refined the lab’s approach but also provided a broader perspective on optimizing future experimental workflows.

Experiential learning and mentorship from industry

While the mentorship at McMaster set the foundations of their passion for biotechnology, the opportunity to introduce an entirely new level of teaching to advance their knowledge was what made the trip to Bohemia one to remember.

Prior to arriving at the Sartorius facility, both students felt that they were going into the site visit equipped with their knowledge from their time at Mac Eng and eager to delve into their learnings even deeper, in a way only professional experience in the industry could provide. They credit the one-of-a-kind mentorship experience with the Sartorius researchers for opening their eyes to what an R&D lab looked like at a commercial level.

“I got to learn from a group of people who I really look up to,” says Shu. “They welcomed us with open arms and had a lot of trust in us to allow us to have a hands-on experience from the very first day we were there.”

As the students reflect on the incredible opportunities they were given, Manager, Applications & Testing at Sartorius Clint Kukla says the feeling of gratitude is reciprocal.

“Welcoming McMaster students to our team at Sartorius has been rewarding; their passion for research and bioprocessing expertise have significantly contributed to our collaborative success,” he says.

Both McMaster and Sartorius have no plans on slowing down their collaboration and are eager to continue to engage in knowledge transfer as the biomanufacturing industry continues to grow.

“The McMaster students have been excellent additions to our team at Sartorius, bringing enthusiasm for the work and a great willingness to learn,” says Charles Prochaska, Scientist of Applications and Testing at Sartorius. “Their fresh perspectives and dedication have enriched our projects, and we look forward to future opportunities to work together.”