Collaborate with us

Industry collaboration is at the core of our research efforts. We can engage in short-term to multi-year technology transfer projects with our industry partners.

Government sponsored programs are available to facilitate University-Industry relationships through Ontario Centres for Excellence (OCE), National Sciences and Engineering Research Council (NSERC) and other programs. These groups offer grants to offset the cost of collaborative projects.

Contact us to improve quality, productivity and cost of your manufacturing processes

Honda of Canada Manufacturing

“Without McMaster’s development of rapid testing to avoid disruption of production, it would not have been possible to get proof of concept to the machining floor quickly.”

Learn more about how the MMRI worked closely with Honda of Canada Manufacturing (HCM) to help address a reduction in tool life due to unique challenges in bi-metal machining.

One of HCM’s highest cost processes in the engine plant is machining the extremely precise bores that the engine’s crank shaft runs in. Precision of these bores directly influences engine efficiency and longevity. Honda’s latest engine design changed these features in an effort to improve efficiency. However, these new changes resulted in a significant reduction in tool life due to the very unique challenges in bi-metal machining (a single tool cutting both aluminum and cast iron at once). As a highly specialized process, very little support was available to address this issue internally and from HCM’s suppliers.

The MMRI team worked closely with HCM. Extensive analysis of HCM’s process and tools was completed by replicating HCM’s process in the MMRI lab. The MMRI identified several short-term solutions to improve tool life and a novel tooling solution to extract more life from each tool (with the idea now patented and implemented in HCM production), while also establishing long-term research initiatives to further improve cost, productivity and quality in this process in the future.

To date, two of the recommendations from the MMRI that represent a significant cost reduction in tooling alone, have resulted in rapid adoption at HCM and have also been implemented at Honda plants across North America. Additional savings are realized indirectly through reduced downtime, reduced scrap due to out-of-tolerance parts, and reduced personnel time in monitoring the process.

“I have been working with the MMRI since 2014, and our relationship has become very comfortable and seamless. We have been able to bounce ideas off each other to bring to test and success both in the MMRI facility and at Honda. The engine’s crank bore project has been the most successful, receiving a patent for the machining process, and without McMaster’s development of rapid testing to avoid disruption of production, it would not have been possible to get proof of concept to the machining floor quickly. The solution from this project was applied to most Honda facilities worldwide, with the same machining processing, and it was presented at all the Honda conferences. The greatest success of this project was being told by the engineer that developed this equipment, ‘they had never thought of machining it this way’. I look forward to continuing our relationship with McMaster and the MMRI team.” – Joe Zarb, Tooling Specialist –Powertrain Division, Honda of Canada Mfg.

Whitebird

“The MMRI has been an amazing partner and without their help, we would never be producing the number of face masks we have been able to achieve.”

Learn more about how the MMRI worked with Whitebird, a Hamilton-based distributor and manufacturer of corrugated solutions, packaging, sanitation, and safety supplies, during the COVID-19 pandemic.

When COVID-19 hit, the MMRI recognized the immediate need for more PPE manufacturing. We reached out to Whitebird, and within two days they had responded that they wanted to team up to manufacture PPE. We spent the next two weeks establishing a supply chain, setting up production, and clearing regulatory hurdles.

The MMRI and Whitebird went from an idea to mass production in less than 3 weeks. We had estimated that we could make 1000-2000 shields per day; on our first day we made 2,800 shields. On our third day we made almost 5,000.

Currently, Whitebird is producing over 65,000 shields per day. Whitebird is now producing the PPE at several assembly areas in the GTA. The MMRI and Whitebird continue to rise to the needs of the public and those fighting COVID-19.

“The MMRI has been an amazing partner and without their help, we would never be producing the number of face masks we have been able to achieve. Working with large organizations can often prove to be very bureaucratic and cumbersome, however our experience with McMaster’s MMRI team has been anything but that. They have been quick to respond, and Simon has felt more like a Whitebird team member than an outside consultant. We look forward working with the MMRI in the future on other exciting projects.” – William Heikoop (Vice President of Whitebird)

ImaginAble Solutions

“I was elated that I finally had a device that would allow me to paint with ease, a hobby I had given up due to shaking and posturing of my dominant hand.”

Learn more about how the MMRI worked with ImaginAble Solutions, a biomedical engineering company that specializes in creating assistive devices for people living with accessibility issues. Their mission is to help people achieve a fulfilling and independent lifestyle by removing physical barriers.

Guided Hands™ was designed to help people living with limited hand mobility caused by Dystonia, ALS, Huntington’s disease, or arthritis, as well as those recovering from spinal cord injuries and strokes, among other conditions. For these individuals, the ability to write, paint, draw, or use a tablet/computer is essential to their independence. Guided Hands™ increases self-esteem, creates opportunity, and allows the user to do what they love.

ImaginAble Solutions’ research and development began at the MMRI. Multiple prototypes were designed and manufactured and then tested with patients at local hospitals, nursing homes, and rehabilitation clinics. The feedback was presented to engineers at the MMRI and used to redesign and manufacture the next prototype.

By partnering with the MMRI, ImaginAble Solutions has minimized research and development costs and manufacturing costs and has received excellent design and manufacturing advice for Guided Hands™. They have successfully invented Guided Hands™ and are commercializing their product with the continued help of the MMRI as they launch their first round of sales.

“I was elated that I finally had a device that would allow me to paint with ease, a hobby I had given up due to shaking and posturing of my dominant hand. Guided Hands™ has given me the freedom to do the things I loved – from painting to playing games on my iPad.” – Elissa, student with Dystonia

Oakville Stamping & Bending

“As it turns out, their research team ended up helping me develop an even more efficient detaching method from my original design. I don’t know what I would have done without McMaster.”

Learn more about how the MMRI worked with Oakville Stamping & Bending: a leading Manufacturer and Distributor of Plumbing Products.

Ontario hospitals were looking for anti-microbial solutions to prevent the spread of bacteria from room to room through plumbing fixtures. The partner required support in “design for manufacturability” of a new “p-trap” design made from exotic anti-microbial material.

The MMRI performed an iterative design exercise and created a final prototype for collaborative testing with OS&B. A year-long research testing is being done within seven GTA hospitals on this product.

All parts are fabricated in Ontario, which means this design is bringing more work to Canadian machining and casting subcontractors. MMRI’s functionality improvements have meant positive projections for the economic future of OS&B.

“As it turns out, their research team ended up helping me develop an even more efficient detaching method from my original design. I don’t know what I would have done without McMaster.” – Chris McLeod (R&D product designer for OS&B)

BioHex Dental Implant Testing Machine

“I would like to congratulate you and your team at McMaster Manufacturing Research Institute for the engineering design of the testing apparatus specific for our application in Implant Dentistry.”

Learn more about how the MMRI is working with Biomedical Implant Technology Inc. to work toward a dental implant can that an replace the industry standard.

The client developed a new style of dental implant called the BioHex Dental Implant. It is their hope that their dental implant can replace the industry standard, but it requires testing to determine its viability and usable life.

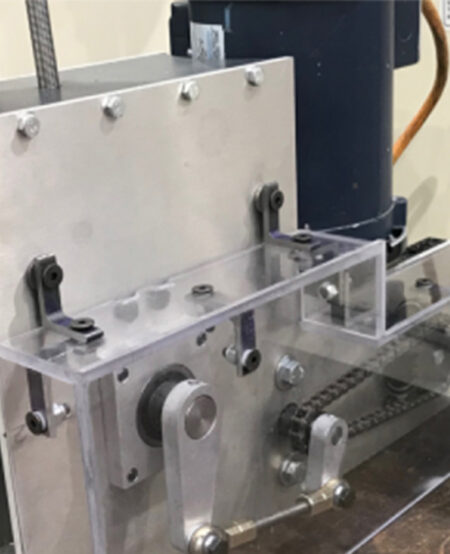

The MMRI team designed and developed a desktop machine capable of mimicking years of chewing in a controlled fashion. The machine can be run for hours or millions of chewing cycles and the dental implants can be easily monitored.

Testing is still ongoing. The economic impact will not be known until the end of 2019.

“I would like to congratulate you and your team at McMaster Manufacturing Research Institute for the engineering design of the testing apparatus specific for our application in Implant Dentistry. The chewing machine, the load cell and software are simple and robust. The applied load was adjustable and constant throughout the testing period. The design of the position measuring device is simple, accurate and reproducible. The data obtained was reliable and the conclusions drawn would be meaningful. Thanks again for meeting and exceeding our requirements.”

– Dr. Kwan, CEO of Biomedical Implant Technology Inc.

Voestalpine

“This would be impossible to do without McMaster. Without having their expertise involved, we wouldn’t be competitive.”

Learn more about how the MMRI worked with Voestalpine: an international steel-based technology and capital goods group. It is the leading supplier of tubular components and assemblies for automotive occupant restraint.

Voestalpine wanted to develop the world’s best process for producing ultra-high-volume components in Ontario.

The MMRI helped the local manufacturing facility with extensive forming experience to expand to machining. When this project is complete, it will be the world’s most competitive process for producing these parts.

Before the MMRI’s contribution, vRSC’s $50 carbide drills would last for roughly 500 drilled holes before breaking, but by the project’s end, that number rose to 10,000 holes drilled per tool. This innovation has brought in millions of dollars in new business and has meant adding five more automated production lines to vRSC’s Burlington facility. This drilling technology is now being adopted around the world.

“It’s a tremendous success, and especially unheard of because we’re drilling on a round surface is very tough material. This would be impossible to do without McMaster. Without having their expertise involved, we wouldn’t be competitive.”

– Andy Skrepnek, vRSC’s Director of Innovation

NORLOK Technology Inc.

Learn more about how the MMRI worked with NORLOK Technology Inc., who is a trusted leader and innovator in sheet metal fastening, setting the standards in clinching technology.

NORLOK asked the MMRI to provide a hand-held clinching device using pneumatic actuators. Clinching, also known as press joining, is a high-speed, mechanical fastening technique for point joining of sheet metal components. Clinching requires no consumables or pre-drilled holes and is performed in a single step, making it a clean, inexpensive and simple technique.

By partnering with the MMRI, NORLOK was able to access extensive R&D resources to punch above their weight in developing a new product and access a new market.

By partnering with the MMRI, NORLOK was able to reduce the research and development demands on their internal resources. This new development represents a niche market that NORLOK can now access. The potential sales from this new market segment are estimated at $150,000 to $200,000.