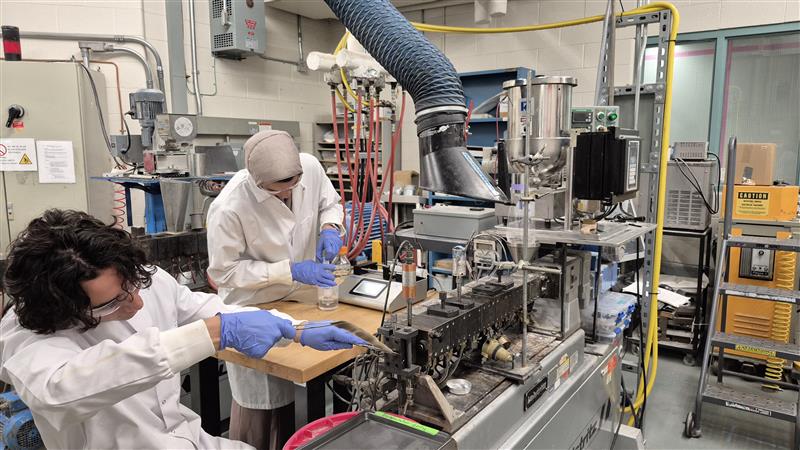

CAPPA-D, housed within the McMaster Manufacturing Research Institute (MMRI), focuses on research, education, and technology transfer in the fields of polymer processing and rheology.

Ongoing projects explore the formulation, conversion, and characterization of plastics, as well as the mathematical modeling of processes such as single and twin-screw extrusion, coextrusion, injection molding, thermoforming, rotational molding, film blowing, reactive extrusion, mixing, and coating.

CAPPA-D’s work is supported through research grants and contracts from the Natural Sciences and Engineering Research Council of Canada (NSERC), Centres of Excellence (Ontario) and a range of Corporate partners across Canada, the United States, and Internationally.

Sintering, Role of Rheology, Bubble Formation and Removal, Foaming, Material Characterization, Micropellets, Metal Metallocene, and Polyethylenes, Recycling

Modeling of Solids Conveying, Melting Metering, Barrier Screws, Extrusion Dies

Kneading Disk Simulation, Flow Visualization

Modeling of Bubble Formation, Property Prediction

Viscosity, Elasticity, Processing Behaviour

Multilayer Slot Coating Visualization and Simulation, Air Knife Coating

Degradation Studies, Compounding for Property Improvement

Experiments and Modeling of Molecular Weight Distribution Modification

Polymer Blends, Additives, Filler

Mailing Address

McMaster University

Department of Chemical Engineering

John Hodgins Engineering Building, Room 374

Hamilton, Ontario, Canada, L8S 4L7