From automating gel manicures, to preventing the spread of diseases amongst drug users, to helping visually impaired people cross the street safely, this year’s capstone projects aim to solve a wide range of real-world problems.

This Thursday and Friday, 57 projects from 214 students will be showcased at the Electrical & Computer Engineering (ECE) and Engineering Physics expos.

For participating final-year engineering students, the expos represent the culmination of a year’s work and a chance to demonstrate both theoretical and applied skills. Each team was required to identify a complex engineering problem and then work as a research and development unit to solve it.

Learn about three projects that will be showcased at the events:

oomi

The brains behind oomi: Cam Bignell, Devan Wagner, Mitchell Kurnell and Leanne Dias

Program: Engineering Physics

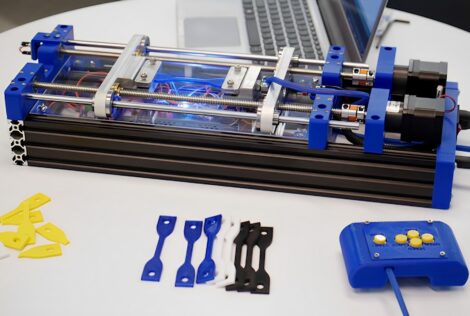

What is it: oomi automates the process of gel manicures using image processing and precise motor control. The device won second place at the 2018 Ontario Engineering Competition and will represent Ontario at the Canadian Engineering Competition in March 2018. The team is in the process of securing a provisional patent for oomi.

Why it matters: In the U.S. alone, there are 400,000 nail technicians. Half of them report health related concerns with their work due to inhalation of the toxic fumes as well as ergonomic-related injuries. This cost-efficient device is intended to help small nail salons improve the health of their workers and increase revenues by servicing more customers.

How it works: To use oomi, the client places their hand on the platform and presses a button to activate image processing of the hand. A camera takes photos of the fingers and detects the edges around the fingernails. It uses the image to determine where the brush should move to coat the nail. The locations are sent to a motor system, which dips the brush into the polish bottle and paints the nail. When painting is complete, the user places their hand in a UV curing module to dry the nails.

When engineering meets the beauty industry: “We thought it was a unique opportunity to apply everything we’ve learned throughout our undergraduate career to an industry that people might not always think of as something that engineers can help innovate,” says Mitchell Kurnell.

SharpXChange

The brains behind SharpXChange: Megan Goodland, Erik Riemers, Mitchell Lemieux and Ashley Gilbank

Program: Engineering Physics

What is it: A needle exchange vending machine for safe injection drug use and disposal.The device is intended to support existing public health resources for drug users such as needle exchange programs and safe injections sites. SharpXchange can be available for 24/7 and users can remain anonymous.

Why it matters: In 2015, 60% of hepatitis C transmission in Canada was due to injection drug use. SharpXChange helps prevent the spread of HIV and hepatitis C, which is prevalent amongst injection drug users who share needles that are unclean.

How it works: Using image detection, the device can identify when a used needle is placed inside the slot. The machine safely disposes of all objects, but will only offer a replacement needle if a used one is identified. The user can browse the needle size options and select a clean needle.

Supporting public health efforts:“My sister volunteered for a needle exchange program and they did their best,” explains Megan Goodland. “They had a truck that went to different places. But if someone is not willing or able to come to the truck, they get left behind. Drug addiction is prevalent in a lot of big cities. If SharpXChange was placed in public areas in the public, it would be easier for people to have access to clean needles.”

VisioAid

The brains behind VisioAid: Daniella Eliathamby and Richard Hamilton, biomedical and electrical engineering; Nilou Keshmiri, electrical engineering and management; Anthony Nahed and Ammar Abughazaleh, electrical engineering students

What is it:VisioAid is a compact, wearable technology that helps visually impaired people navigate safely at crosswalks. The device detects walk and stop signs as well as obstacles through video and image processing a sensor and microcontroller. The VisioAid team is working on custom glasses that will house the camera.

How it works:To activate the device, the user turns a switch on. The system uses a raspberry pie to process the information, isolating an image of the walk sign, removing all background details.A watch uses Bluetooth and a microcontroller to communicate with the processing unit, letting the user know when it’s safe or unsafe to walk through a vibration or audio output.The system also has a sensor that notifies the user when there is an obstacle up to 2 metres away.

A volunteer program that sparked the idea: “Richard and I are part of an after school program for children in Hamilton called Mathstronauts,” explains Daniella Eliathamby. “One of the projects we worked on was a visual aid detection system for visually impaired people. It was very small-scale using ultrasonic sensors and that sparked the idea for a need for more visual impairment aids.”

Future development: “VisioAid could be integrated with GPS to develop an autonomous wheelchair that plans a safe path for the user,” adds Nilou Keshmiri.