The electric vehicle (EV) industry is on the cusp of a paradigm shift. The gap between EVs and internal combustion engine vehicles is narrowing, thanks to significant investments from both industry and government, as well as the impending 2030 Emissions Reduction Plan.

With the potential for reduced purchase prices, improved range and shorter charging times, Canadians are increasingly ready to embrace EVs. However, despite the progress, a gap still remains. Researchers at McMaster Engineering believe that it will take the ingenuity of engineers and innovators to fully unlock the potential of an electrified future.

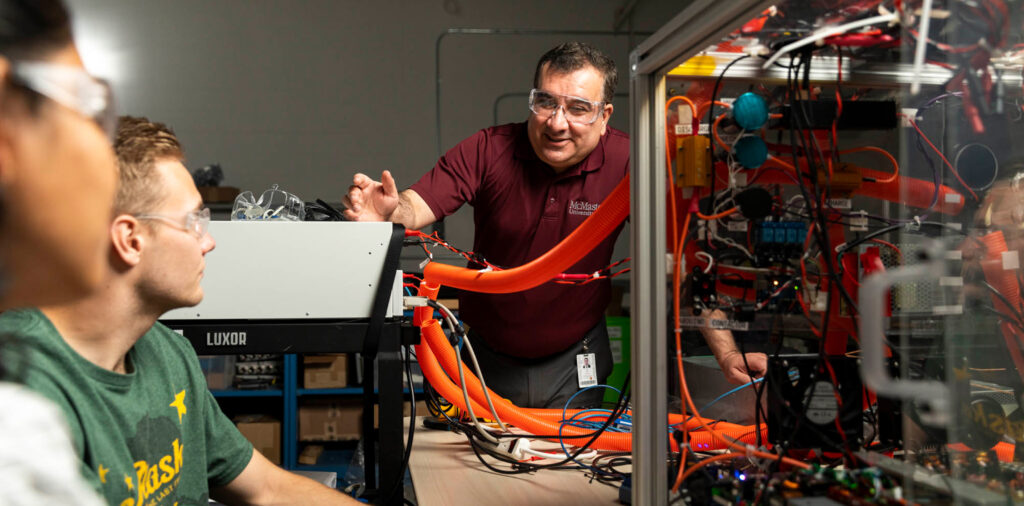

“Vehicle electrification is no longer a niche market, but a global trend driven by economic, environmental and societal imperatives,” says Ali Emadi, Canada Research Chair in Transportation Electrification and Smart Mobility, and NSERC Industrial Research Chair in Electrified Powertrains. “For Canada to stay competitive in this industry, we need to expand our research capacity and infrastructure.”

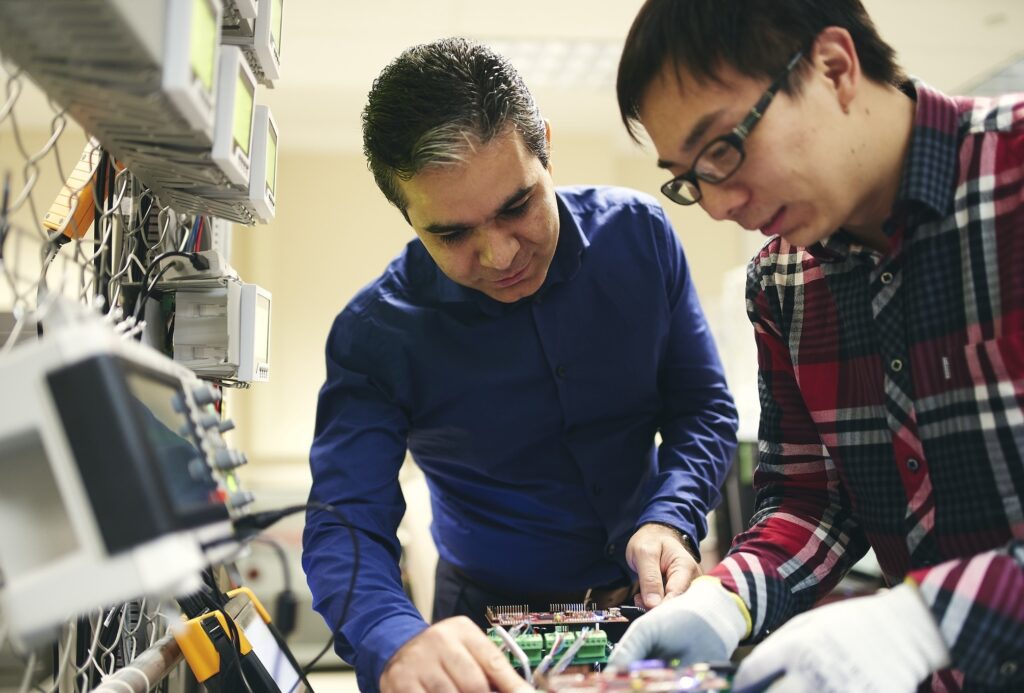

Emadi has led the efforts at the University to establish the McMaster Automotive Resource Centre (MARC) as a prominent North American hub for research, innovation and experimentation. Since its inception 15 years ago, MARC has provided academics and industry partners with access to cutting-edge facilities and the expertise of faculty and graduate students, driving advancements in automotive electrification. Mehdi Narimani, an Associate Professor of Electrical and Computer Engineering and Canada Research Chair in High Power Converters, brings to MARC extensive expertise in power electronics, semiconductor device applications and EV chargers to the team. His knowledge is crucial in advancing power conversion technologies, which are essential for the development of fast EV chargers.

“MARC is a world-class facility for electrification, and we are looking forward to continuing the momentum and building on the success to continue to address the ever-changing needs of the EV industry,” says Narimani.

Emadi and Narimani envision MARC also as a hub for developing the next generation of EV charging technologies and bi-directional vehicle-to-grid (V2G) charging systems.

Beyond batteries: A full suite of experimental capabilities

While the rise of battery gigafactories is crucial to meet the growing demand for EVs, Emadi and Narimani believe that enhancing EV performance requires more than just producing battery cells and materials.

“Producing a battery is one step of the car manufacturing process, but going from battery cells to battery packs (including battery electronics and management systems) and the compatibility of the battery with additional powertrain components of EVs provide great opportunities for improvements,” explains Emadi.

Once the battery cells are ready for installation, they must be tested alongside other battery pack components, including electronics, balancing circuits, protection devices, connectors, sensors, battery management systems, thermal management and packaging. This additional need is a crucial aspect of the supply chain that needs more attention, and MARC aims to bridge this gap.

“With a Centre as unique as ours, we can give researchers and industry the opportunity to integrate battery packs with EVs and put their work to the test,” says Narimani.

For example, if someone is developing a new material for a battery cell, MARC provides the facility to test their work in the context of its application. This means not only testing the battery cell but also evaluating it within a battery module, a battery pack, an electric vehicle powertrain, and an electric vehicle.

MARC’s distinctive offering allows for showcasing new technology and testing, characterizing, verifying, calibrating and improving it. By providing access to comprehensive testing inside an electric vehicle, MARC significantly accelerates the development of EVs.

This, in turn, will increase access to more affordable EVs and charging systems, helping to address the needs for lower-cost and longer-range EVs that could be charged quicker. Emadi and Narimani envision this space not as an exclusive McMaster facility but as a center for all research universities, small and midsize enterprises and auto industry partners to leverage.

Beyond the experimental capabilities that Emadi and Narimani foresee for MARC’s next phase, there are significant opportunities to train the next generation of skilled engineers and technical personnel in the automotive and energy sectors.

“We’re well-positioned to embrace the electrification renaissance,” says Emadi. “The future is bright.”

________________________________________________________________________________

Learn more about the McMaster Automotive Resource Centre.